When it comes to flexible materials in manufacturing, plastic sheets have become a mainstay across various industries due to their durability, flexibility, and broad range of applications. Among the numerous kinds of plastic sheets readily available in the market, products like PVC cling film, ABS plastic sheets, and high impact polystyrene (HIPS) sheets are especially noteworthy.

On the other hand, ABS plastic sheets are renowned for their stamina and impact resistance, making them ideal for a range of applications, consisting of industrial, vehicle, and consumer products. The white ABS plastic sheet is specifically favored in industrial applications where appearances and ease of cleansing are paramount.

The production of ABS sheets includes a durable process that guarantees their resilience and high performance. Thermoforming sheets use heat to reshape plastic right into wanted types, making it a cost-effective selection for mass manufacturing.

In comparison, HIPS plastic sheets present a lighter alternative that preserves particular mechanical attributes similar to ABS. Known for their outstanding steam or vacuum forming attributes, HIPS sheets are popular in product packaging and display screen applications. Their residential or commercial properties enable intricate layouts that can additionally supply a visually appealing coating, making them appropriate for consumer items.

Moving beyond common plastic sheets, composite plastic sheets offer a sophisticated solution that incorporates several materials to boost performance. These composite sheets offer special benefits such as improved strength-to-weight proportions and increased resistance to ecological elements, making them ideal for applications in building, automotive, and aerospace markets.

An additional considerable gamer in the plastic sheet market is polyethylene (PE) sheets, understood for their convenience and chemical resistance. Vendors of PE sheets often supply a variety of choices, consisting of high-density polyethylene (HDPE) sheets, which are specifically helpful in sturdy applications and as liners in different frameworks. HDPE sheets are widely utilized in farming, building and construction, and even for making containers. Manufacturers often creating these sheets make sure that they are made from high-quality materials that adapt security and conformity criteria, making them ideal for various applications.

As sectors evolve, so does the need for top quality plastic products. Today's market is swamped with various suppliers and providers dealing with particular requirements-- from fabric leather made from PVC to specialized plastic sheets like ABS and HIPS. This comprehensive variety allows organizations to choose the best sort of plastic sheet that fulfills their precise specifications, get more info consequently maximizing their production processes and enhancing product resilience.

The integration of sophisticated innovations in the manufacturing of these plastic products has yielded substantial enhancements in their top quality and application variety. Developments in additive production and 3D printing have additionally opened new opportunities for custom-made plastic applications, promoting making use of materials like ABS, HIPS, and composite sheets in producing prototypes and end-use items. As customers end up being a lot more knowledgeable about ecological elements, the concentrate on recyclable products has likewise surged, triggering manufacturers to explore lasting choices without jeopardizing on top quality.

Flexibility is a critical characteristic of contemporary plastic sheets, promoting their use in a variety of settings-- from day-to-day household products to complicated equipment components. The ability to cut or control sheets right into particular measurements, such as the usual 4x8 layout, significantly enhances their functionality throughout various tasks. Customers can easily discover white ABS sheets read more or choose personalized dimensions depending on their unique needs, guaranteeing that they always have the best material for the job.

Besides their physical residential properties, plastic sheets are additionally preferred for their visual capacities. White ABS sheets are usually selected for their smooth, modern finish, which fits seamlessly right into modern style themes. This adaptability in layout factors to consider further drives their popularity throughout several industries, where aesthetic allure can be simply as crucial as performance.

As industries come to be progressively competitive, the choice of products can considerably influence a firm's functional effectiveness and bankability. The facility of dependable collaborations with sheet makers and website providers can additionally be a game-changer, enabling businesses to source high-grade materials constantly. Collaborating with relied on service providers makes certain that companies are constantly stocked with the needed products, be it HDPE sheets for robust applications or adaptable PVC fabric leather for fashion items.

In summary, the selection of plastic sheets offered today, consisting of PVC cling hips, film and abs sheets, and composite plastic choices, reflect the impressive adaptability in the use of plastics throughout sectors. With enhancements in production strategies, a focus on sustainability, and an expanding taste buds of materials, the future of plastic sheets appears poised for growth, guaranteeing also higher technologies and applications in the years to come. The continuous dialogue regarding ecological responsibility and recycling can additionally enhance the function of plastic sheets, encouraging markets to take on greener practices while fulfilling consumer demands for top quality and resilience.

Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Danielle Fishel Then & Now!

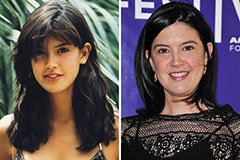

Danielle Fishel Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!